Design Services

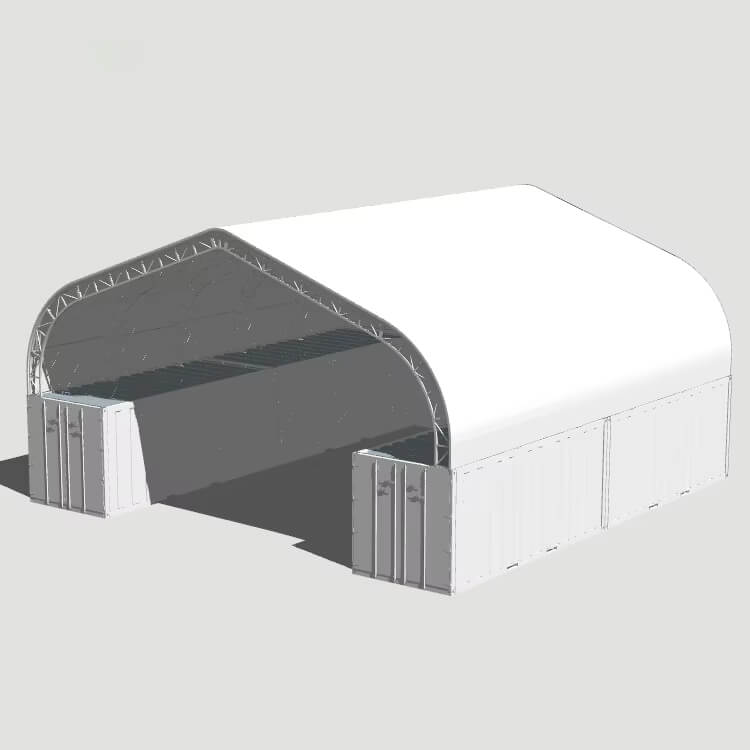

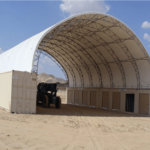

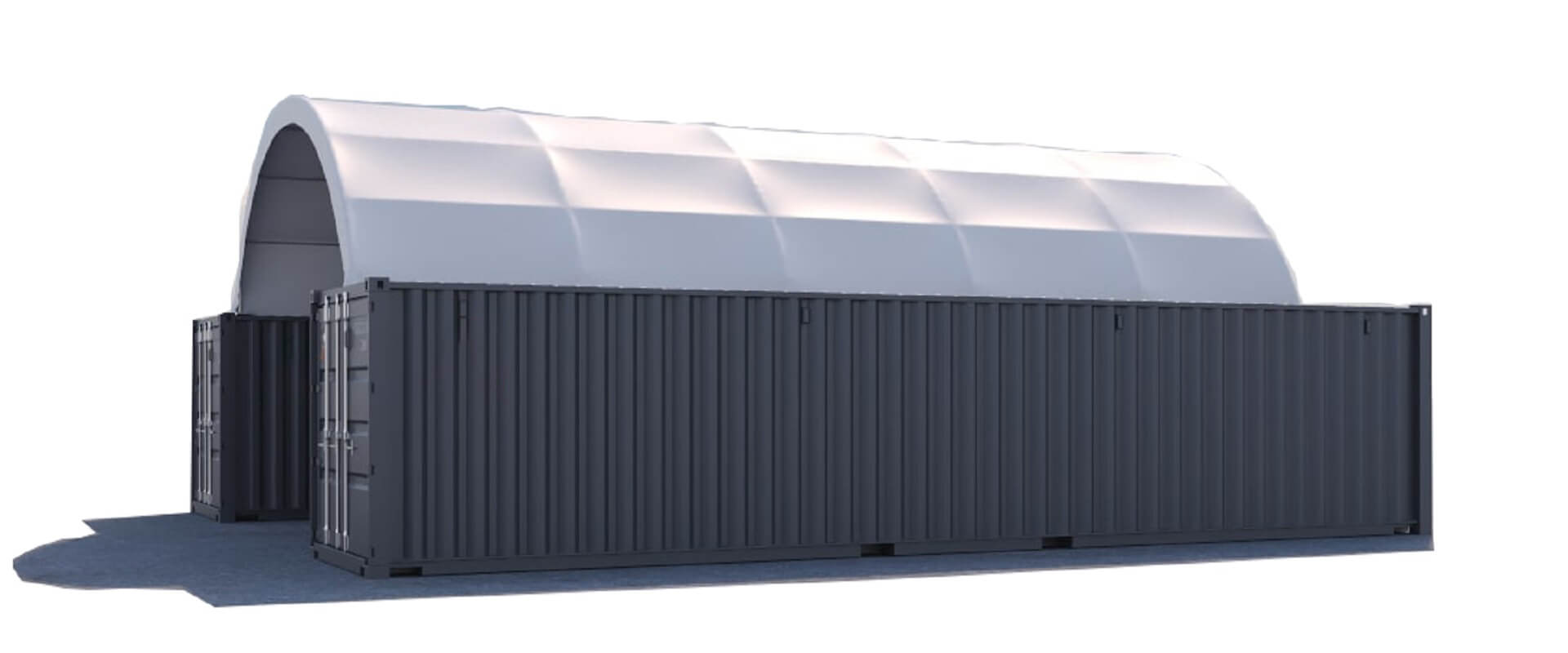

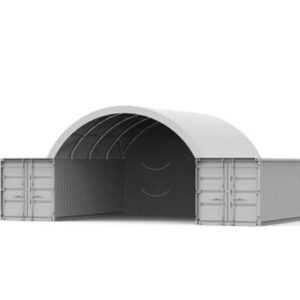

40×40 Large Area Container Canopy – Reliable, Customizable Coverage for Wide Storage or Work Spaces

PRODUCT PARAMETERS

- Frame Material: Metal

- Frame Finishing: Powder Coated

- Sail Finishing: PVC Coated

- Type: Garages, Canopies & Carports

- Pressure Treated Wood Type: Chemical

- Temporary Offices: Provide secure and comfortable workspace for project managers

- Tool Storage: Secure storage for equipment, protecting them from theft and weather

- Break Rooms: Offer a place for workers to rest, eat in a protected environment

- Warehousing: Use as additional storage space for goods and materials

- Supply Storage: Store supplies and equipment securely

- Farm Storage: Store farming equipment, feed, and produce

- Livestock Shelters: Protect livestock from harsh weather conditions

- Durability: Steel is strong durable,making containers resistant to extreme weather

- Quick Setup: Container shelters can be assembled quickly

- PVC Coated Fabrics: PVC-coated fabrics are flexible and waterproof

Description

A container shelter is designed to provide protection and coverage for cargo containers, often used in various settings such as construction sites, military operations, and logistics. The primary purposes of using a container shelter include:

Container shelters protect stored goods from rain, snow, wind, and other environmental factors that could damage or contaminate the contents.

1. Define the Purpose and Requirements:

- Purpose: Determine what the shelter will be used for (e.g., residential, storage, office).

- Occupancy: Consider the number of people who will use the space.

- Location: Assess the site conditions (e.g., climate, terrain, accessibility).

2. Choose the Right Container(s):

- Size: Select the appropriate size based on your needs (e.g., 20ft, 40ft).

- Number: Decide if you need multiple containers and how they will be arranged.

- Condition: Ensure the containers are in good condition and suitable for conversion.

3. Plan the Layout:

- Floor Plan: Sketch out the interior layout, including room dimensions and locations of doors and windows.

- Stacking: If using multiple containers, plan how they will be stacked or connected.

- Structural Integrity: Consult with an engineer to ensure the design is structurally sound.

4. Insulation and Climate Control:

- Insulation: Choose the right insulation material based on the climate and purpose (e.g., spray foam, fiberglass batts).

- Ventilation: Plan for proper ventilation to prevent condensation and mold growth.

- Heating/Cooling: Consider HVAC systems or other methods to maintain comfortable temperatures.

A container shelter is designed to provide protection and coverage for cargo containers, often used in various settings such as construction sites, military operations, and logistics. The primary purposes of using a container shelter include:

- 1. Protectionfrom Elements: Container shelters protect stored goods from rain, snow, wind, and other environmental factors that could damage or contaminate the contents.

- 2. Temporary Storage: They offer temporary storage solutions when permanent structures are not feasible or cost-effective.

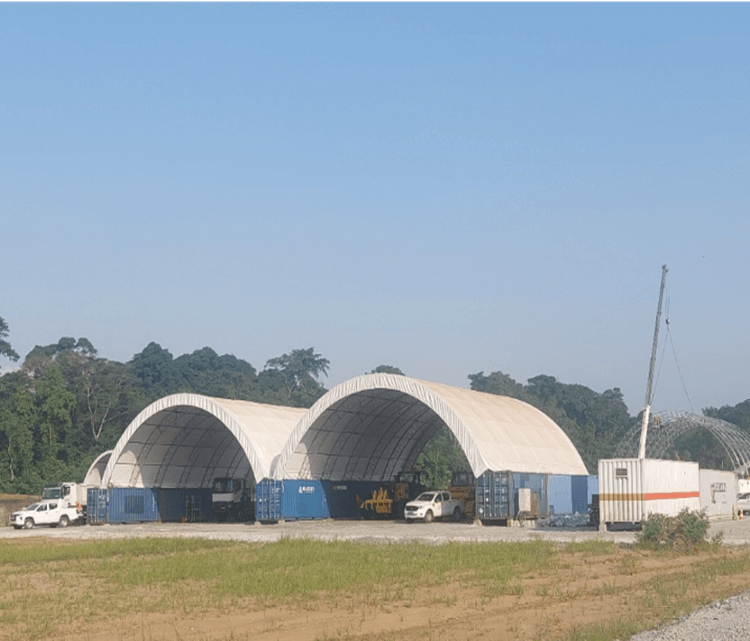

- 3. Customizable Spaces: Shelters can be customized to fit different sizes of containers, allowing them to be used for various applications and needs.

- 4. Easy Setup and Mobility: Container shelters are easy to set up and dismantle, making them highly portable and suitable for temporary use.

- 5. Cost-Effective: Compared to building permanent structures, container shelters are a more cost-effective solution for providing covered storage space.

- 6. Security: They enhance security by providing a covered area where containers can be locked and monitored, reducing the risk of theft or vandalism.

- 7. Versatility: Container shelters can be used in a variety of industries, including construction, military, logistics, and more, making them a versatile choice for different applications. In summary, the main purpose of a container shelter is to provide a protective, secure, and cost-effective storage solution that can be easily deployed and adapted to different needs and environments.

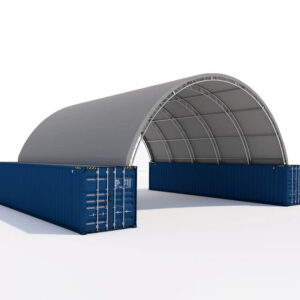

The Standard Size of Container Shelter and be able to customized dimension

The standard sizes of container shelters are typically designed to accommodate the most common sizes of cargo containers, which are 20-foot (6.1 meters) and 40-foot (12.2 meters) containers. Here are the standard sizes of container shelters based on these container dimensions:

For 20-Foot Containers:

- Length: 20 feet (6.1 meters)

- Width: Varies, but typically around 8 feet (2.44 meters) to match the width of the container.

- Height: Varies depending on the design, but generally around 9 to 10feet (2.74 to 3.05 meters) to provide clearance for the container and any additional overhead space needed.

For 40-Foot Containers:

- Length: 40 feet (12.2 meters)

- Width: Varies, but typically around 8 feet (2.44 meters) to match the width of the container.

- Height: Varies depending on the design, but generally around 9 to 10 feet (2.74 to 3.05 meters) to provide clearance for the container and any additional overhead space needed.

Additional Considerations:

- Overhang: Some shelters may have an overhang on each side to provide extra coverage and protection from the elements.

- Customization: Champion Metal Structure manufacturers offer customization options, allowing you to adjust the height, width, and length to better fit your specific needs options to better suit specific requirements. If you need a shelter for a less common container size, such as a 45-foot (13.7meters) container, you should consult with Champion Metal Structure who can provide a custom solution.

Security of Container Shelters Container shelters

Provide varying levels of security depending on their design and construction. Here are some key aspects that contribute to the security of container shelters:

- 1. Material Quality: High-quality materials such as heavy-duty steel frames and durable fabric covers enhance the overall security of the shelter.

- 2. Lockable Entries: Most container shelters come with lockable entries, such as roll-up doors or zippered fabric entrances, which help prevent unauthorized access.

- 3. Anchoring Systems: Secure anchoring systems are crucial for preventing theft and ensuring the stability of the shelter during adverse weather conditions.

- 4. Surveillance Compatibility: Some shelters can be equipped with surveillance cameras and alarm systems for added security.

- 5. Visibility: Transparent or mesh walls can improve visibility, making it harder for intruders to hide and easier for security personnel to monitor the area.

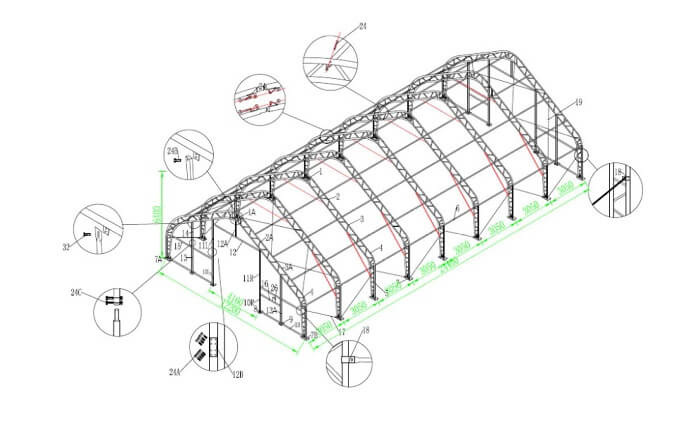

Structure Analysis

Structure analysis is crucial for ensuring the stability and durability of container shelters. Here are the key components of structure analysis for container shelters:

- 1. Load Bearing Capacity: The shelter must be able to withstand the weight of the container and any additional loads, such as snow accumulation.

- 2. Wind Resistance: The shelter should be designed to withstand high winds, which can cause significant damage if not properly engineered.

- 3. Material Strength: The strength of the materials used in the frame and cover is critical. Steel frames and UV-resistant, waterproof fabrics are commonly used for their durability.

- 4. Stability and Anchoring: The shelter must be stable and anchored securely to the ground to resist tipping or being blown away.

- 5. Fatigue Analysis: Components should be analyzed for fatigue to ensure they can withstand repeated loading and unloading cycles without failing.

- 6. Vibration Analysis: Vibration analysis helps ensure that the shelter can handle vibrations caused by nearby machinery or traffic without compromising its integrity.

Structural Design Considerations:

- Frame Design: The frame should be designed to distribute loads evenly and resist deformation under stress.

- Fabric Tension: The fabric cover should be tensioned appropriately to minimize sagging and improve wind resistance.

- Anchoring System: A robust anchoring system is essential for securing the shelter to the ground, especially in areas prone to high winds.

Step 1: Design

- 1. Requirements Gathering: Determine the specifications and requirements for the shelter, such as size, materials, and intended use.

- 2. Design Sketches: Create initial sketches or 3D models to visualize the shelter.

- 3. Structural Analysis: Conduct structural analysis to ensure the shelter can withstand the required loads and stresses.

- 4. Safety Compliance: Ensure the design complies with relevant safety standards and regulations.

Step 2: Material Selection

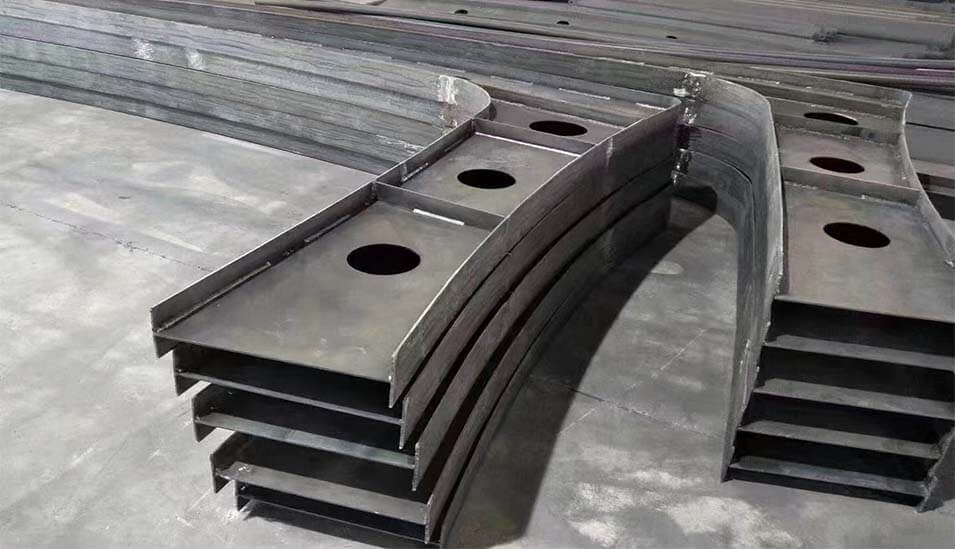

- 1. Frame Materials: Choose high-quality steel or aluminum for the frame, depending on the desired strength and durability.

- 2.Cover Materials: Select appropriate cover materials, such as heavy-duty polyester or PVC-coated fabrics, which are water-resistant and UV-resistant.

- 3. Anchoring Systems: Decide on the type of anchoring system, such as stakes, concrete foundations, or weighted bases.

Step 3: Manufacturing

- 1. Frame Production:

- Cutting: Use CNC cutting machines to cut the steel or aluminum to precise dimensions.

- Welding: Weld the frame pieces together using MIG or TIG welding techniques.

- Finishing: Apply a powder coating or paint finish to protect against corrosion.

- 2. Cover Fabrication:

- Cutting: Cut the fabric according to the design specifications.

- Seaming: Sew the fabric panels together, reinforcing seams as necessary.

- Attachments: Add any necessary attachments, such as zippers, Velcro strips, or D-rings.

- 3. Assembly Hardware:

- Boltsand Nuts: Provide all necessary hardware for assembling the frame.

- Anchors: Include anchors or stakes for securing the shelter to the ground.

Ordering a container shelter involves several steps, from selecting the right type and size to finalizing the purchase. Here’s a step-by-step guide on how to order a container shelter:

- Step 1: Determine Your Needs

- Purpose: Decide on the purpose of the shelter, such as storage, workspaces, or equipment protection.

- Size: Measure the area where the shelter will be placed and determine the size of the container(s) you want to cover.

- Features: Consider additional features you might need, such as ventilation, lighting, and locking mechanisms.

- Step 2: inquiries

- Contact the Manufacturer

- Initial Inquiry: Reach out to the manufacturer via phone or email to inquire about the available models and pricing.

- Customization Options: Discuss any customization options, such as color,size, and additional features.

- Technical Support: Ask for technical support or advice if needed, especially if you have specific requirements.

- Step 3: Request a Quote

- Detailed Specifications: Provide detailed specifications of the shelter you need, including size, materials, and features.

- Budget: Mention your budget to help the manufacturer suggest suitableoptions.

- Delivery Details: Discuss delivery timelines and costs.

- Step 4: Place the Order

- Confirmation: Confirm the order details, including the final price, delivery date, and payment terms.

- Deposit: Pay the required deposit or full payment as per the agreement.

- Documentation: Receive and review any necessary documentation, such as contracts or purchase orders.

- Step 5: Prepare for Delivery

- Site Preparation: Prepare the site where the shelter will be installed, ensuring it is level and clear of obstructions.

- Installation Services: Inquire about installation services if needed.

- Tools and Equipment: Gather any necessary tools and equipment for installation.

- Step 6: Receive and Install the Shelter

- Inspect Upon Arrival: Inspect the shelter upon arrival to ensure there are no damages or missing parts.

- Professional Installation: If professional installation is provided, schedule a convenient time for the installation team.

- Self-Installation: If you are installing the shelter yourself, follow the manufacturer’s instructions carefully.

FAQs

Yes. Customized logos can be printed on the tent fabric according to your requirements.

Yes. We assure you all prices are based on factory. We are an experienced tent factory, providing competitive prices, direct quality control, and flexible production scheduling. Our factory has 2 advanced welding robots, 8 welding machines, 2 shearing machines, 10 punching machines, 4 bending machines, 2 sinking machines, 2 heat sealing machines, 10 sewing machines and many professional production workers. In order to assure high quality products and services to customers, all of our operations are strictly conducted in accordance with the ISO 9001: 2008 quality control systems.

Our tents can be assembled and dismantled easily and repeatedly with small transportation size. The lifespan of aluminium framework can reach 15-20 years, and 5-8 years for PVC fabrics depending on different conditions of usage.

A full range documents including structural drawings, packing list, installation manual and relative certificates can be provided. Moreover, customs declaration is provided. We provide one-stop service for you.

You can contact with our sales team, telling us what kind of event you are going to hold, and how many people you are going to accommodate. We will offer a suggestion according to your event usage and required capacity.

Regular size tents will take about 25-35 working days after receiving deposit. You can contact Zhongke team to further discuss based on the specific tent and quantity.

REQUEST A QUOTE

RELATED PRODUCTS

4080ft Heavy-Duty Shipping Container Canopy Shelter – Built to Withstand Harsh Weather and Provide Reliable Coverage

20ft Sturdy Container Canopy – Built for Long-Lasting Protection, Perfect for Medium-Sized Storage Solutions

Premium Container Canopy for All-Weather Protection – Ideal for Storage and Outdoor Uses

Customizable Container Canopy Metal Steel Sheds & Storage Storage Building 12 X 12 Waterproof Classic Powder Coated