Design Services

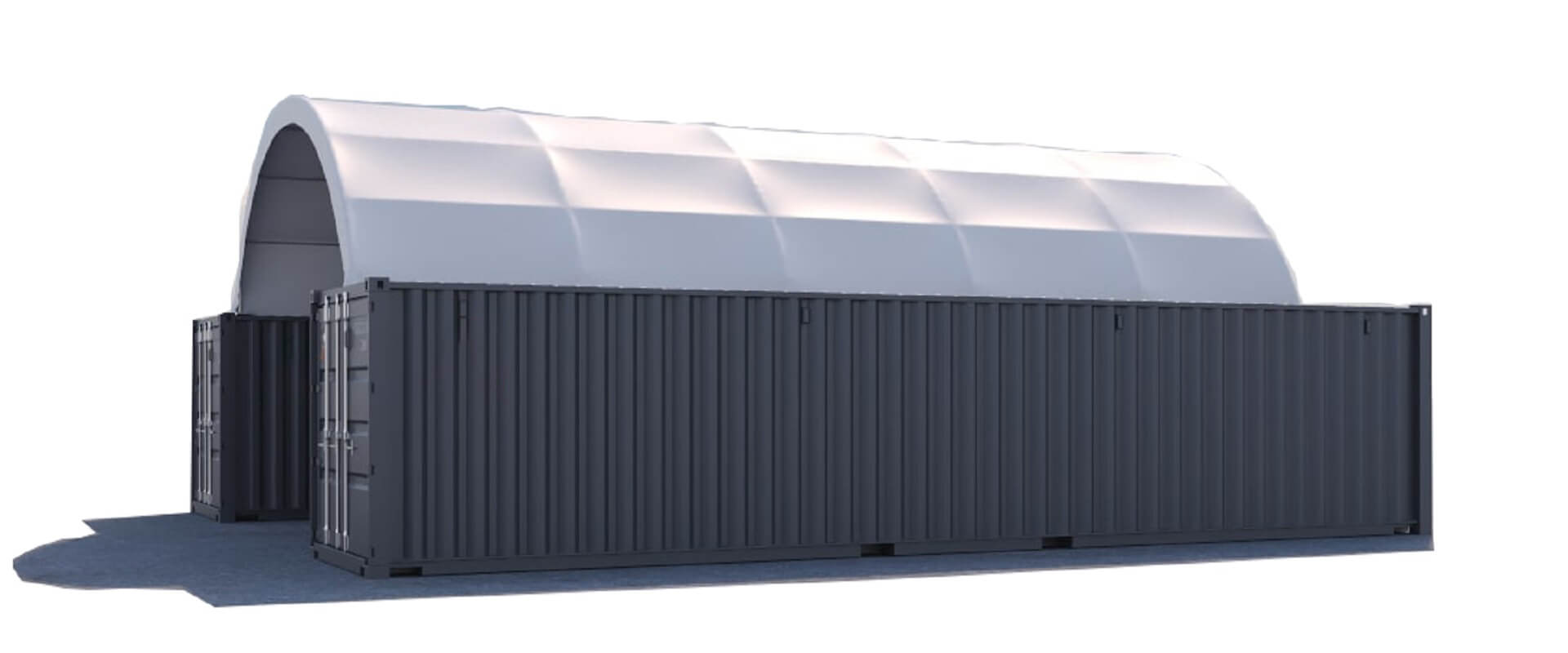

20x40m pvc outdoor tennis basketball canopy court roof tent

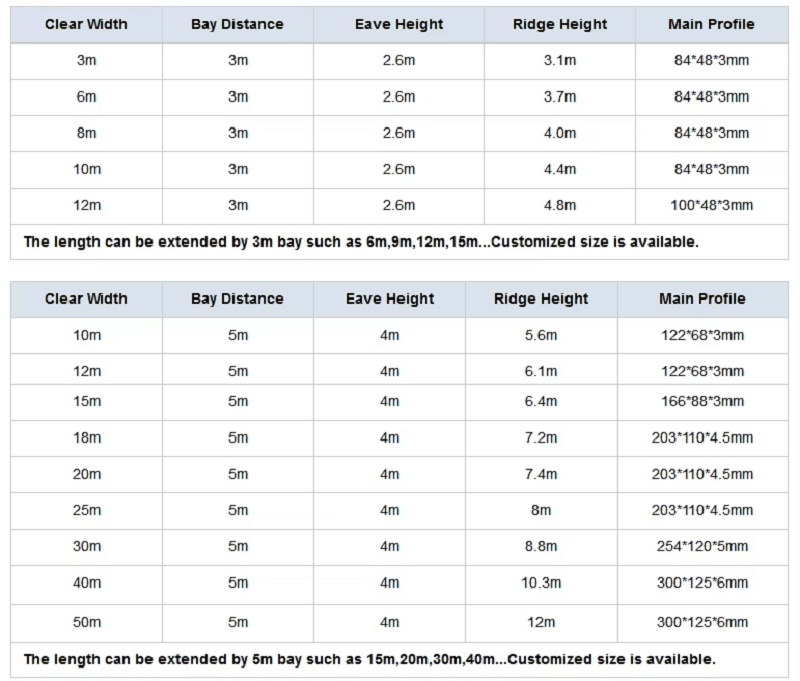

PRODUCT PARAMETERS

- Frame Material: 100% CE certified aluminum alloy profiles T6061/T6 with anodized surface.

- Service life: > 25 years.

- Outer Fabric: 100% Fire retardant DIN 4102 b1 level, light-blocking out, waterproof and UV resistant, 850g/sqm double side PVC coated polyester fabric

- Snow Load: 75kgs/sqm.

- Wind Resistance: 100-120km/h.

- Temperature Resistance: -30 to +70 Celsius.

- Note: Frame and fabric can both be reinforced depending on weather conditions of installation city.

Description

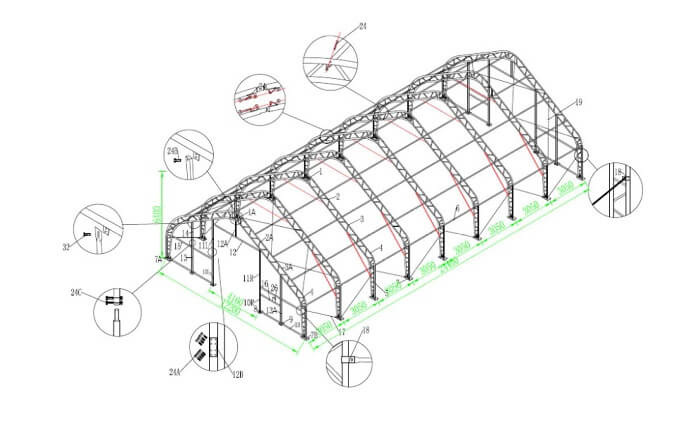

This design allows for a sturdy structure that is able to withstand strong winds and other environmental elements. The curve structure tent is typically made of lightweight and durable materials, such as aluminum or PVC, and can be used for a variety of outdoor events and activities, such as weddings, festivals, and camping trips.

The unique design of the curve structure tent also provides a spacious and open interior, making it ideal for large gatherings or events.

Main Frame: High Reinforce Aluminum, anti-rust surface, GB6061-T6 ;100%”FENGLV “Aluminum Material Guaranteed; It can be used more than 25 years.

Fabric Cover: 850g/m² and 650g/m² Double PVC-Coated Polyester, flame retardant, UV resistance, waterproof, comply to DIN 4102 B1( European standard) – Perfect Fabric Cover Brand in China Recently. Connector: HotDIPPED Galvanized Steel Connections; 100% Zinc Shine Hot Dip Galvanizing Guaranteed.

Allowed Temperature Condition: -40°to +70°temperature

Max Wind Speed Allowance: 100km/h

Snow Load: 75kgm

Easy to be assembled and dismantled, movable.

No pole inside, tent space can be 100% utilized.

Tarpaulin:

Zhongke tents’ tarpaulin is synthesized by PVC knife scraping coating Fiber cloth, weight is 650g-850pcs/m².

We work with upstream manufacturers to develop PVDF and Substrate impermeable suction technology two surface treatment technologies Applied to traditional tarpaulins,

not only waterproof performance Well, it also has effects such as flame retardant.

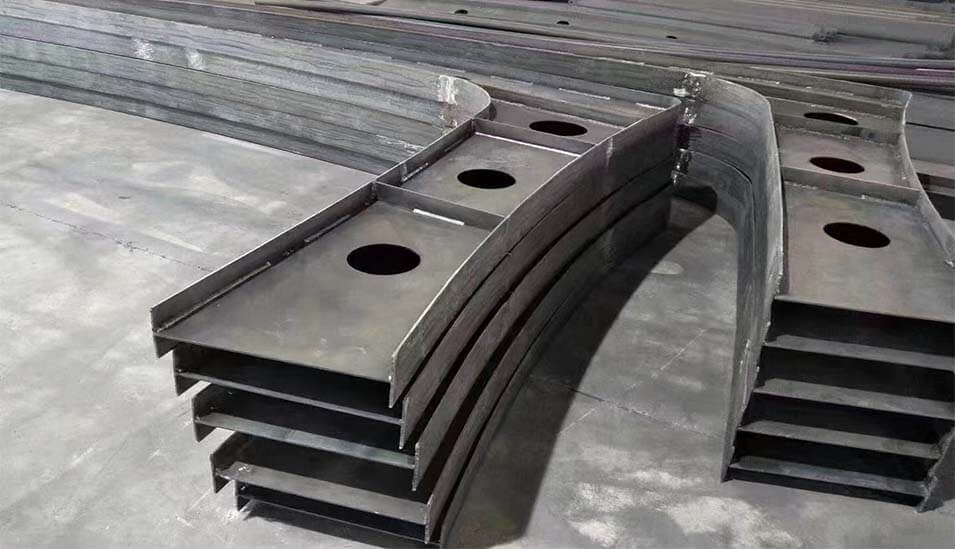

Aluminum alloy:

Most of the aluminum profiles of Zhongke tent bracket use 6082-T6/6061-T6 aluminum alloy profiles, and the surface hardness can reach 15-16HW.

The oxygenation film thickness ≥ 10-15μm, which ensures the service life of the aluminum.

Features of steel structure membrane hangar:

1. Cost-effective: About 1/3 to 1/2 lower than conventional structures on costs.

2. Short Construction time: Half time is saved compared to the traditional buildings.

3.Various Shape: Changeful supporting structure can make lots of different shapes of membrane structure with flexible membrane.

4.Seurity: Membrane Structure can keep the good stability under the action of horizontal load such as earthquake.

5.Self-Cleaning: The rain getinto water to down on the surface of membrane and clean itself.

6.Fireproof: Fireproof performance of membrane structure can fill the requirements of US ,French,Germany ,Japan and other contries.

7.Large Span:The largest span of Tension membrane structures can exceed to 200m.

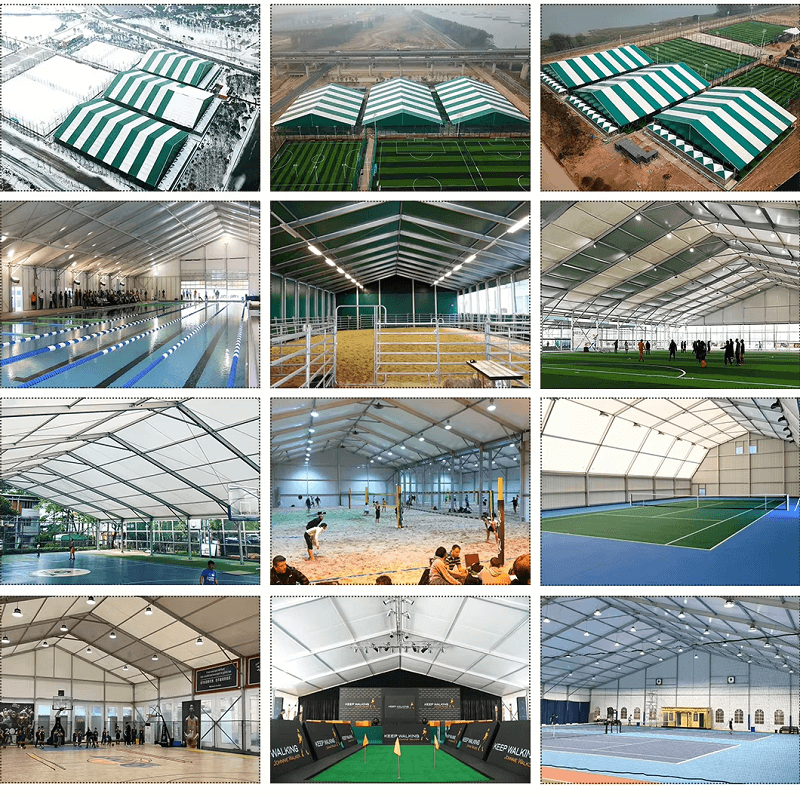

We offer many kinds of tents with different sizes to meet your needs.

- Small pagoda tent:3x3m,4x4m,5x5m,6x6m,8x8m,10x10m.

- Span of roof tent:3m,6m,8m,10m,12m,15m,18m,20m,21m,25m,30m,35m,40m,45m,50m 60m and so on,or according to your requirement. The length can be extended by 3m or 5m as your need.

- Polygonal tent: hexagonal tent,octagonal tent,decagonal tent,ect.

- Special tent: like roof tent with a high peak

- Other customized tents are available.

FAQs

Yes. Customized logos can be printed on the tent fabric according to your requirements.

Yes. We assure you all prices are based on factory. We are an experienced tent factory, providing competitive prices, direct quality control, and flexible production scheduling. Our factory has 2 advanced welding robots, 8 welding machines, 2 shearing machines, 10 punching machines, 4 bending machines, 2 sinking machines, 2 heat sealing machines, 10 sewing machines and many professional production workers. In order to assure high quality products and services to customers, all of our operations are strictly conducted in accordance with the ISO 9001: 2008 quality control systems.

Our tents can be assembled and dismantled easily and repeatedly with small transportation size. The lifespan of aluminium framework can reach 15-20 years, and 5-8 years for PVC fabrics depending on different conditions of usage.

A full range documents including structural drawings, packing list, installation manual and relative certificates can be provided. Moreover, customs declaration is provided. We provide one-stop service for you.

You can contact with our sales team, telling us what kind of event you are going to hold, and how many people you are going to accommodate. We will offer a suggestion according to your event usage and required capacity.

Regular size tents will take about 25-35 working days after receiving deposit. You can contact Zhongke team to further discuss based on the specific tent and quantity.