Design Services

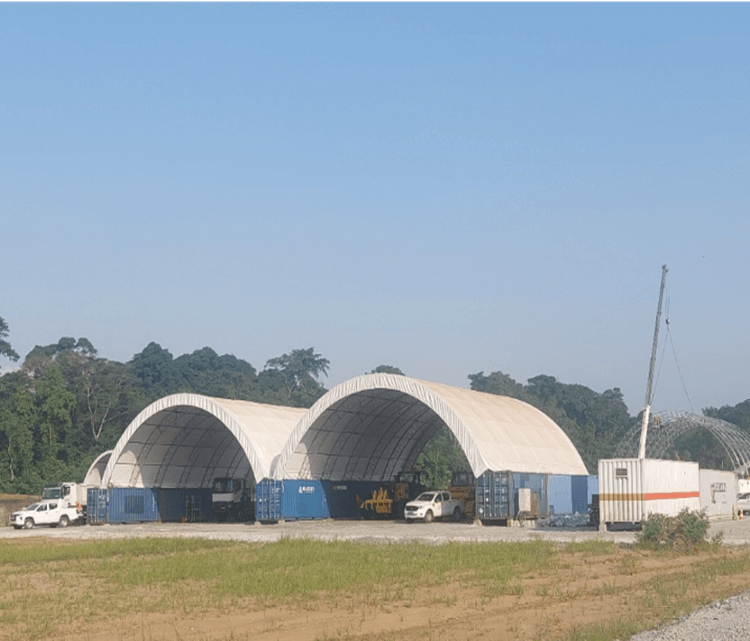

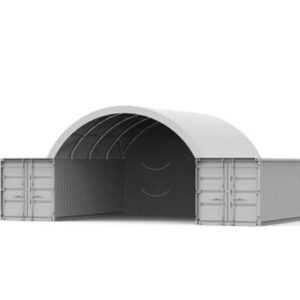

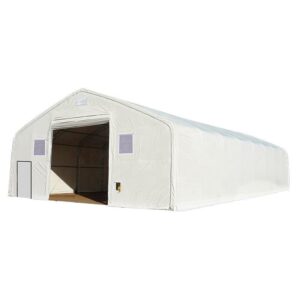

How to make a 20ft container shelter

A 20-foot (about 6 meters) container shelter is a small, flexible and economical building solution suitable for living, storage or emergency places. The following are the steps to make a 20ft container shelter.

1. Preparation and planning

- (1). Identify the needs:

- Living use: Consider lighting, ventilation, insulation and internal functional layout.

- Storage use: Pay attention to waterproofing, anti-theft and stability.

- Other uses: If it is a temporary office or camping site, unique features such as power systems or mobility designs can be added.

- (2). Draw a design plan:

- Internal layout: Determine door and window openings, furniture placement and partitions.

- Exterior design: Whether it is necessary to add a roof, decorate the exterior walls or install other structures.

- (3). Budget estimate:

- List the costs of container procurement, modification materials, tools and labor, and reserve a certain budget to deal with possible additional expenses.

2. Materials and tools preparation

- Materials:

- 20ft container: Choose a second-hand or new container in good condition.

- Insulation materials: such as polyurethane board, rock wool or glass fiber wool.

- Waterproof materials: waterproof coating, sealing strips.

- Decorative materials: wood board, gypsum board, PVC floor.

- Foundation materials: concrete blocks or steel beams to support the foundation.

- Tools:

- Welding machine, electric drill, cutting machine.

- Measuring tools, painting tools.

- Crane or forklift (for transporting and placing containers).

3. Foundation preparation

- (1). Foundation construction:

- Choose a concrete foundation or steel beam support according to the terrain to ensure that the foundation is level and solid.

- The foundation height should be slightly higher than the ground to avoid rainwater soaking.

- (2). Container placement:

- Use a crane to transport the container to the foundation location.

- Check the levelness of the container and adjust the support points if necessary.

4. Container modification

- (1). Cutting and opening:

- Open doors and windows on the container according to the design.

- Reinforce and weld the cut area to prevent the structural strength from being damaged by cutting.

- (2). Insulation and heat preservation:

- Lay insulation materials such as foam board or rock wool on the inner wall, ceiling and floor.

- Use wooden boards or gypsum boards to seal the insulation layer to increase the aesthetics and comfort.

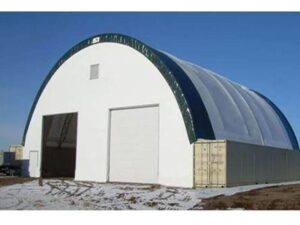

- (3). Roof reinforcement:

- If it is used for a long time, a roof slope or awning can be installed to prevent water accumulation and direct sunlight.

- Install drainage gutters on the roof to facilitate the drainage of rainwater.

- (4). Interior decoration:

- Install partition walls according to the purpose, and configure furniture or storage facilities.

- Install circuit systems, including lighting, sockets and electrical wiring.

- If there is a need for heating or cooling, air conditioning or heating equipment can be installed.

5. External treatment

- (1). Anti-corrosion coating:

- Apply anti-rust paint or waterproof paint on the outside of the container to extend its service life.

- The exterior wall can be decorated with wood grain board, color steel plate or other beautification materials.

- (2). Installation of doors and windows:

- Install anti-theft doors and windows to ensure safety.

- Double-glazed windows can be selected to improve thermal insulation performance.

- (3). Supporting facilities:

- Add awnings, canopies or corridors outside the container.

- Simple small courtyards or fences can be laid to improve the overall environment.

6. Completion and acceptance

- (1). Test function:

- Check whether the doors and windows open and close smoothly and whether the seals are intact.

- Test whether the circuits and ventilation equipment are operating normally.

- (2). Acceptance criteria:

- Ensure that the structure is stable, waterproof and moisture-proof, and has good thermal insulation.

- Check whether it complies with the design plan and adjust the details.

7. Subsequent maintenance

- (1). Regular inspection:

- Regularly check the roof drainage system, external coating and sealing.

- Clean up any debris that may have accumulated to prevent water from flowing smoothly.

- (2). Repair and upgrade:

- Upgrade functions as needed, such as adding solar panels or water filtration systems.

- Repair damage or corrosion in a timely manner to extend the service life.

Building a 20ft container shelter is a flexible and scalable construction project. From planning to completion, all it takes is reasonable design and efficient execution to create a sturdy, beautiful and practical shelter space. Whether it is for short-term use or long-term residence, this solution can meet a variety of needs.